In HVAC, manufacturing, airflow, fit, and durability are everything. From ductwork to custom housings, precision in sheet metal cutting directly impacts system performance. Traditional dies can be a barrier to fast innovation and cost control.

Challenges in HVAC Component Manufacturing:

- Die changes slow down model updates

- Prototyping is expensive and time-consuming

- Scaling up production takes longer due to tooling dependencies

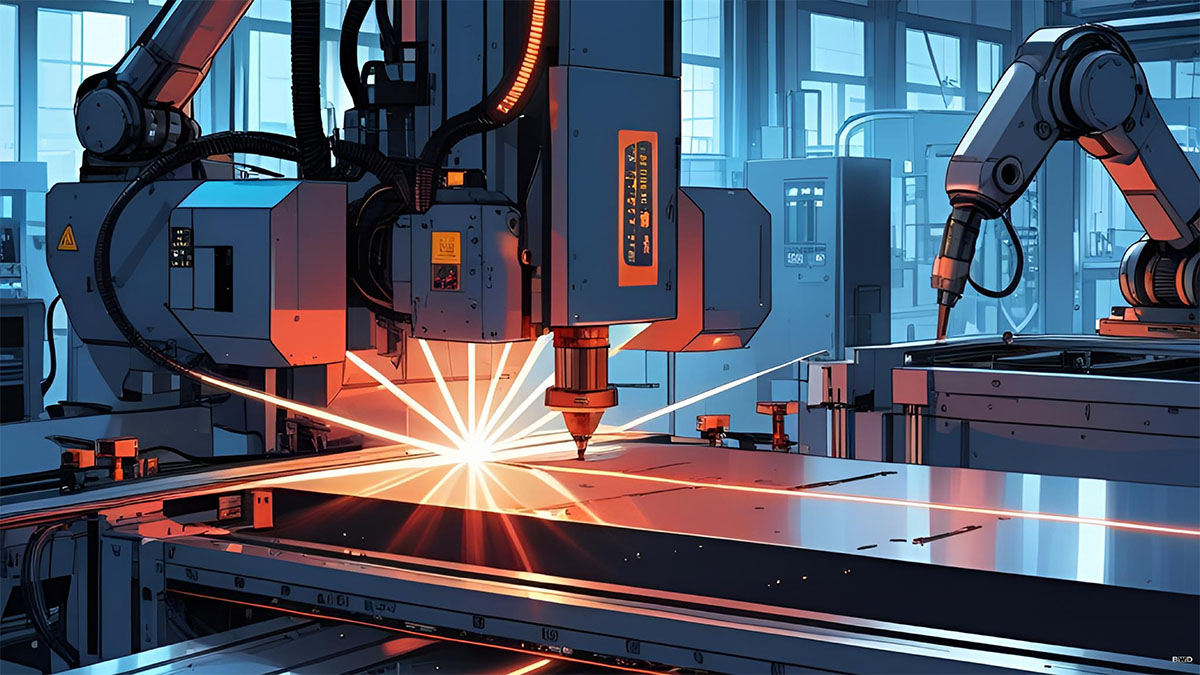

Why HVAC Manufacturers Are Turning to Laser Blanking:

- Adjust quickly to custom orders or seasonal needs

- Eliminate tooling costs

- Use material-efficient layouts for aluminum, galvanized steel, or stainless steel

Key Benefits:

- Precision cuts for tighter airflow control

- Minimal burrs = less post-processing

- Faster turnaround for new housing and vent designs

For HVAC manufacturers seeking cost savings, agility, and quality, high-speed laser blanking offers a smart path forward.

Ready to rethink your HVAC manufacturing workflow? Request a quote today.