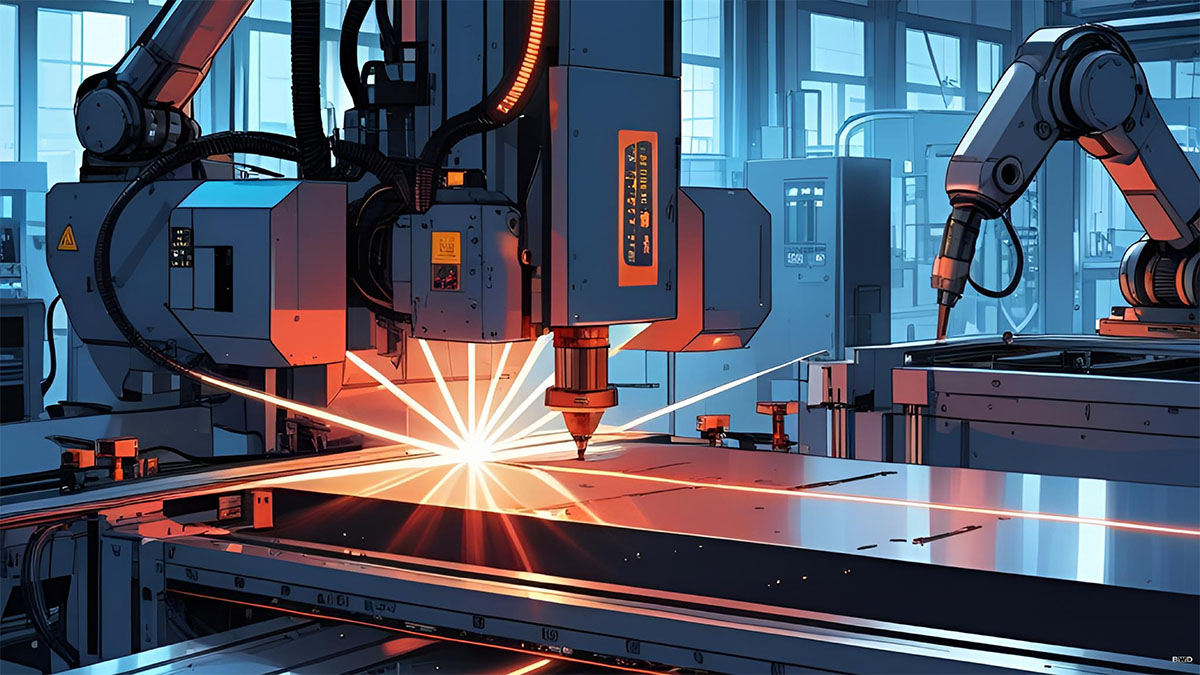

Why Traditional Metal Blanking Is Losing Ground to Laser Technology

January 9th, 2026

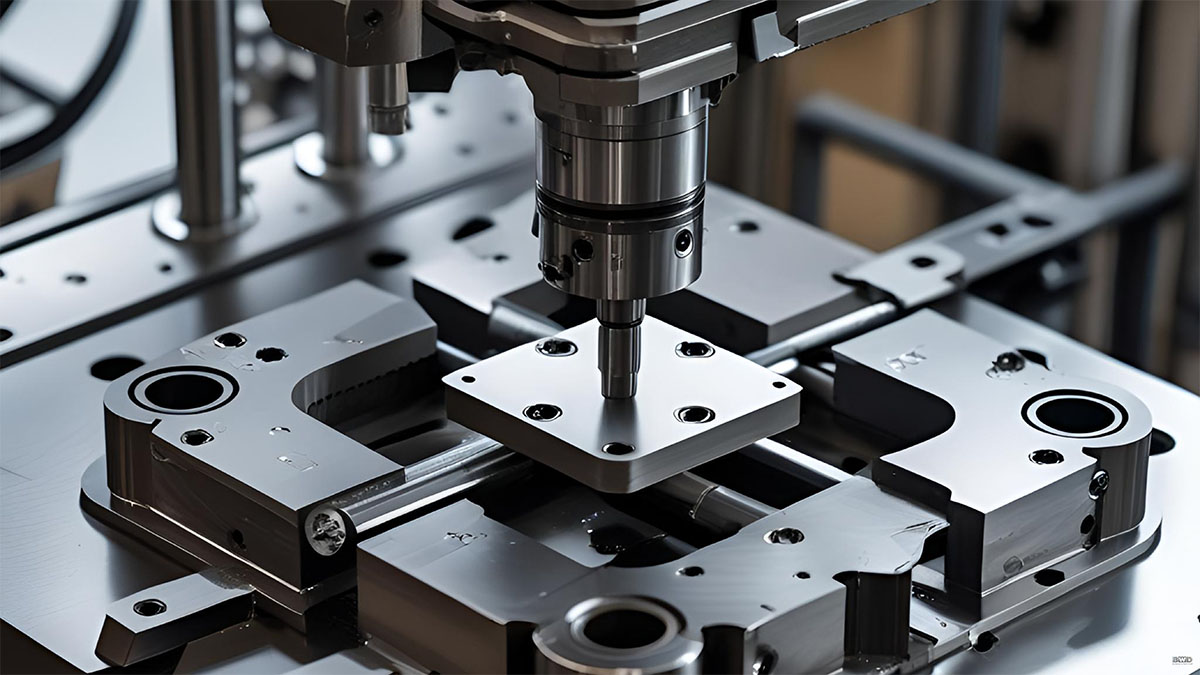

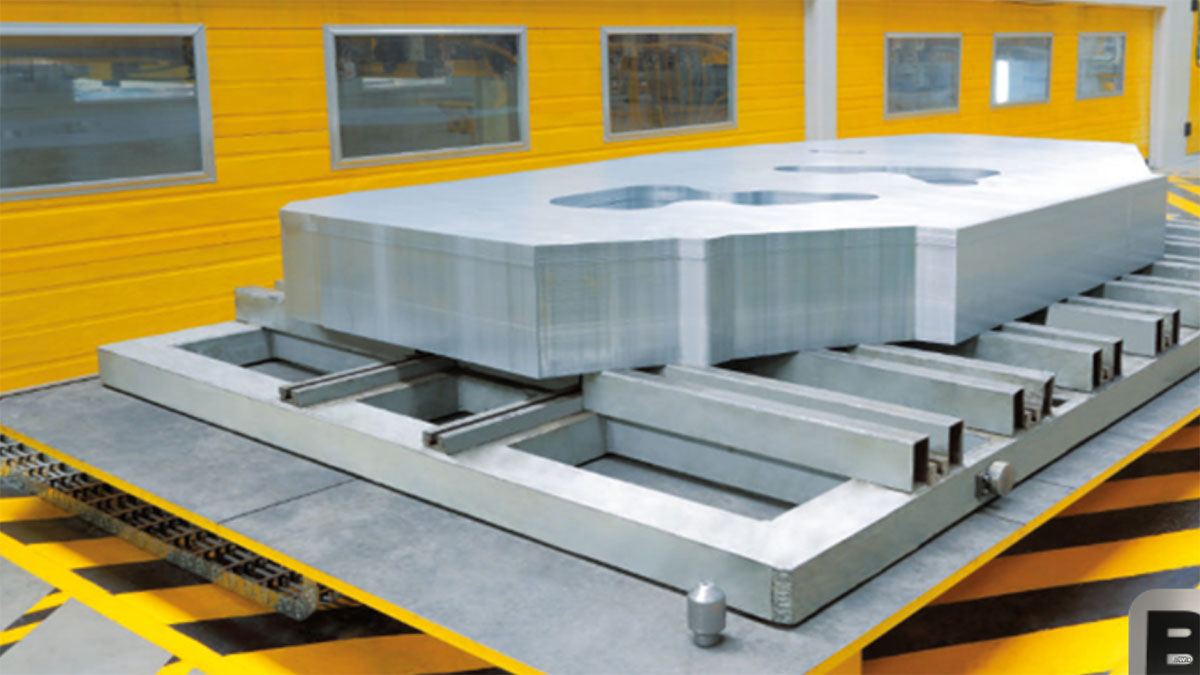

For decades, traditional metal blanking has been the backbone of automotive and industrial manufacturing. Mechanical blanking presses, stamping dies, and progre...