You’ve got the idea. You’ve built the CAD model. Now all you need is a fast way to test it in the real world. But traditional tooling takes weeks to set up and costs more than a prototype should. That’s where BWD Technologies can help.

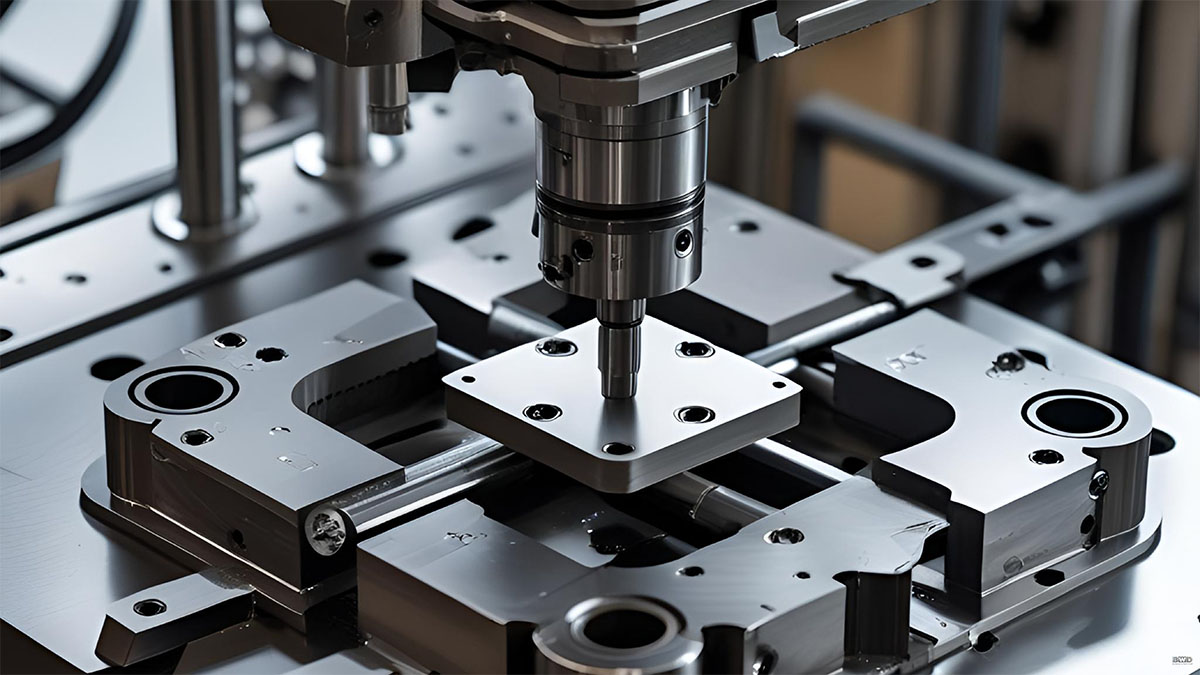

Our die-less metal blanking service is built for rapid prototyping. Whether you’re refining a new design or preparing for production, we help you move fast without compromising on quality.

When you’re using dies, every design change requires a pause. You wait for tooling. You pay for revisions. You burn through timelines and budgets just trying to get one part in your hands.

For product teams working under tight deadlines or exploring multiple versions of a part, that process just doesn’t work.

With BWD’s high-speed laser blanking, we take your digital design and turn it into finished sheet metal parts—quickly, cleanly, and without the need for physical tooling.

Here’s how it helps:

We work with:

And because we offer material-efficient laser cutting, your prototype is not only fast and accurate—it’s cost-effective and environmentally smarter too.

Need your metal prototype next week, not next month?

Let’s make it happen. Request your quote now.