Value Proposition

Us vs. Traditional Blanking

High Speed Digital Laser Blanking is M4.0 enabling:

Lower operating cost.

Light-weight digital manufacturing – (lower upfront investment, speed to market)

Near location supply chain.

BWD Unique Value Propositions to Customers

We deliver cost savings, BIC quality, and minimize investments for low-cost derivatives.

Cost Savings - Material costs savings with increased utilization

Material Utilization Design (MUD) shared saving with customers

Material yield optimization with intelligent nesting – Scrap reduction and offal usage

Master coils instead of slit coils or nonstandard coils

Quality Improvement – eliminate rework and quality issues at stamping plants

No burrs, no micro fractures, etc. – reduced rework and no trimming

Reduced surface damages and less dirt on surfaces on outer panel (class A) blanks

Superior edge quality and mechanical properties

Investment Efficiency – Support low-cost derivatives strategy

Flexibility and metal agnostic – Steel, Stainless, AHSS, UHSS etc.

Upfront engineering blank design and nesting optimization to maximize cost savings at Start of Production (SOP)

Faster Speed to Market – BWD Flexible manufacturing approach

Reduces capital expenditures with blank dies

BWD digital approach handles variants and complexity without the associated cost penalties

Eliminate tool refurbishment cost and tooling engineering changes

Support sustainability and carbon footprint mission

Clean sustainable technology with very lean carbon footprint

Lower energy usage per blank

Cost Benefits

Lower Total Cost of Ownership (TCO) compared to alternatives

• Near net shape “edge-to-edge” blanking

• Optimized in coil arrangements

BWD eliminates the need for physical die change overs and delivers inline production cutting speeds.

BWD delivers superior cut edge quality and blank cleanliness across all materials (especially for advanced high strength steels). Laser welding ready edges do not require an additional precision shearing operation.

BWD eliminates die amortization and maintenance costs.

Competitive Advantages

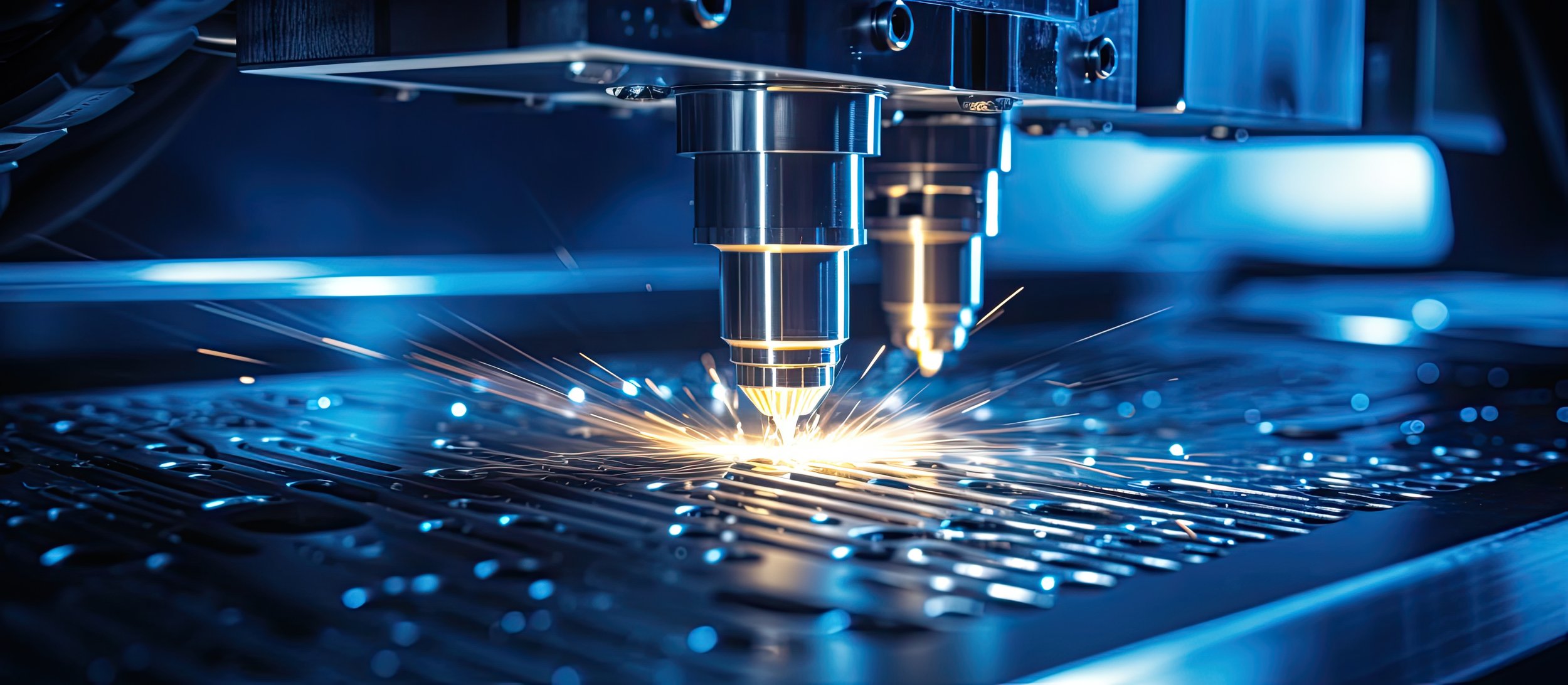

High Tech Laser Blanking

Speed To Market

Manufacturing Agility

• Provides platform for ideal blank shape and nesting. Increasing material utilization up to 5%

• Delivers superior edge quality across all materials (critical for adv. high strength steels, aluminum)

• Reduces direct labor requirement (operators/material handlers) versus conventional process

• No dies investment, die storage or die maintenance.

• Change perception of critical blank shape capability

• Integrate with laser welding of multiple monolithic blanks removing to improve yield

• Blanking as a service business model

To Be Determined via future partnership and joint efforts

Platform Lifecycle Savings

• $11-22 million from material utilization

•. $3 million in die cost reductions

• $5 million in logistics freight & inventory

• Transitions seamlessly from part run to part run, single coil batch runs.

• Minimizes pallet change over via modern high-speed stackers with robot assist and CNC programming

• Supports multi-blank within coil manufacturing

• Reduces non-value added scheduling and prep administrative activities

• Eliminates die & tooling engineering from critical path

• Simultaneous & iterative multi blank shape concept testing

• Supports blank performance testing via CAD/ simulation capabilities (no hard tool tests). Fast Trial Validation.

• Critical path lead time

• Concept to blank turnaround

• Minimized design and test material usage

• 10% processing speed improvement

(uptime & material handling)

• 20% reduction in indirect on-value added time

Future Product & Process Improvement

Material Utilization & Resource Efficiency

Laser and Stacker specs

Laser and Stacker specs are Best In Industry: Productivity and Quality

Fiber Optic Laser Specs

Bandwidth of 0.2mm. Focus point

Higher power at 4 kilowatts.

LB Mill Edge = 8mm/edge

5 axis (up, down, front, back, angled)

Compressed Air to cut (min. dust)

Stacker – 2 drop stacker

Current Lasers in NA

Bandwidth of 4.0mm

Power 2 kilowatts

Mechanical slit Mill Edge = 10 mm/edge

2 axis

Nitrogen to cut

Single or manual stacking

Quality: Delivers BIC Blank Cleanliness

Our System Approach

Clean room – eliminates sources of contamination.

Double washers, before and after laser box.

Laser technology that delivers burr-free blanks.

Vacuum system and compressed air to extract all dust

Best In Industry washer systems remove all containments down to 15 microns. (Hair = 15 microns)

Material Utilization Improvements

Our System Approach

Clean room – eliminates sources of contamination.

Double washers, before and after laser box.

Laser technology that delivers burr-free blanks.

Vacuum system and compressed air to extract all dust